Closed conveying, no leakage, no emissions

Custom specifications, flexible process matching

Automatic operation

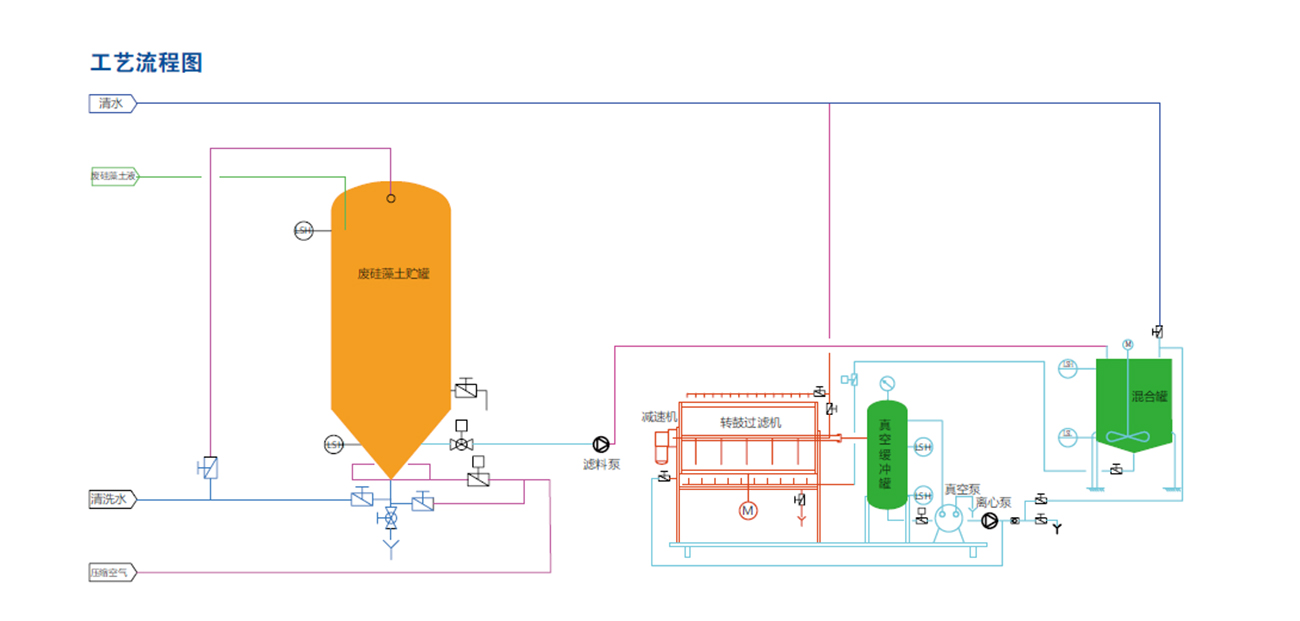

| System main configuration or composition | Features |

| Waste diatomite storage tanks; | The integrated filter drum can make the pre-coating evenly distributed and easy to clean. |

| Mixing tank (with stirring); | With anti-cleaning function, to ensure that the equipment is cleaned from the inside to the outside. |

| Drum filter, unloading mechanism and frame; | Continuous automatic operation, low labor intensity. |

| Buffer tank; | The speed of the filter drum is controlled by frequency conversion to obtain filter cakes with different humidity requirements. |

| Pump: filtrate pump, centrifugal pump, vacuum pump; | The equipment has a compact structure, a small footprint, simple operation, smooth and reliable work. |

| Valves, pipe fittings; | |

| Control System. |

| The main technical parameters |

| Main material: SS304; |

| Filtration area: 2.5 ~ 6m2; |

| Drum diameter: ¢ 600 ~ 1000mm; |

| Working pressure: -0.2 ~ -0.6bar; |

| Processing capacity: 100 ~ 300kg / (about 60% water content) or mixed liquid 1.5 ~ 2.5m3 / h; |

| Total installed capacity: 10 ~ 13kw; |

| Area: 10 ~ 15 m2; |

|

Dimensions:2700×1500×1600mm 3800×2600×2700mm |

|

Working principle |

Control System |

|

Vacuum drum filter equipment is mainly used for waste diatomite liquid treatment, so it is also called waste diatomite Device. This equipment is driven by a reducer to continuously rotate the filter drum at a uniform speed. The vacuum pressure difference formed by the filter drum Suction filtration, water in the material liquid is continuously sucked into the tank for discharge or recovery; and solid materials (Such as diatomaceous earth) is evenly adsorbed on the outer surface of the drum to form a filter cake layer. With a certain thickness, the scraper in the discharge area is automatically fed to the cutting cake layer. The solid material is continuously cut into the receiving trough and bagged. Cycle like this Continuous suction filtration operation, separate the discharged water from the filter residues to be discarded, to achieve environmental protection, health Health requirements. |

This system adopts PLC programming automatic control and touch screen panel setting, which can realize pre-coating and filtering.    |