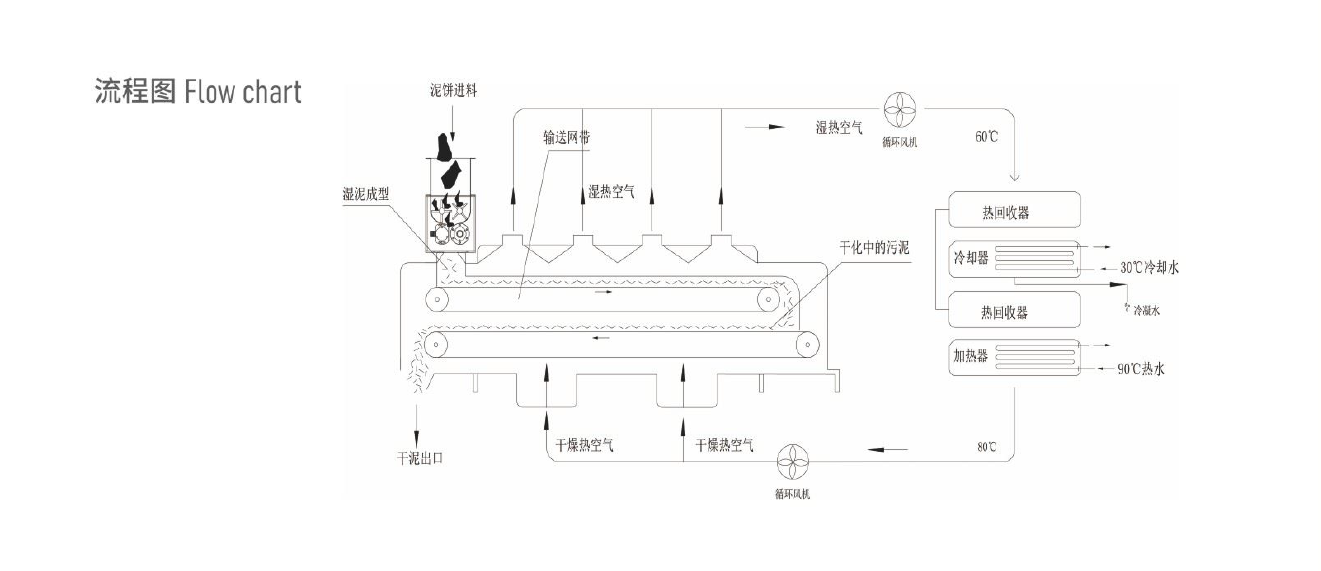

Waste heat utilization, heat recovery and utilization, energy saving 30%

Moisture content below 10%, reduction over 80%

Ultra-low operating cost per ton of mud at 50 kWh

50 degrees low temperature operation, safer

0 emissions, no odorous emissions, condensate can be discharged straight, more hygienic without dust

|

Model |

JCW5000 |

JCW10000 |

JCW15000 |

JCW20000 |

JCW25000 |

JCW30000 |

JCW35000 |

JCW40000 |

JCW45000 |

JCW50000 |

|

Standard water removal / 24h |

~5000kg |

~10000 kg |

~15000kg |

~20000 kg |

~25000kg |

~30000 kg |

~35000kg |

~40000 kg |

~45000kg |

~50000 kg |

|

Water removal / h |

~208 kg |

~416 kg |

~624 kg |

~832 kg |

~1040 kg |

~1248 kg |

~1458 kg |

~1667 kg |

~1857 kg |

~2083 kg |

|

Operating power |

13kw |

26 kw |

39 kw |

52 kw |

65 kw |

78kw |

91kw |

105kw |

117kw |

130kw |

|

Standard heating power |

200 kw |

400 kw |

600 kw |

800 kw |

1000 kw |

1200 kw |

1400 kw |

1600 kw |

1800 kw |

2000 kw |

|

Hot water flow

(90 ℃ -70 ℃)

|

8.6m3/h |

17.2m3/h |

25.8 |

34.4m3/h |

43m3/h |

51.6m3/h |

60.2m3/h |

68.8m3/h |

77.4m3/h |

86m3/h |

|

Standard cooling power |

180kw |

360kw |

540kw |

720kw |

900kw |

1080 kw |

1260 kw |

1440kw |

1620kw |

1800 kw |

|

Cooling water flow

(33 ℃ -45 ℃, Δt = 12 ℃)

|

13m3/h |

26m3/h |

39m3/h |

52m3/h |

65m3/h |

78m3/h |

91m3/h |

105m3/h |

117m3/h |

130m3/h |

|

Number of modules |

1set |

2set |

3set |

4set |

5set |

6set |

7set |

8set |

9set |

10set |

|

Overall dimensions mm |

4800 *3150 *3250 |

8020 *3150 *3250 |

11270 *3150 *3250 |

14520 *3150 *3250 |

17770 *3110 *3200 |

20920 *3150 *3250 |

24570 *3150 *3250 |

27520 *3150 *3250 |

30770 *3150 *3250 |

34020 *3150 *3250 |

|

Structure type |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

|

Equipment weight |

5.6Ton |

9Ton |

12.3Ton |

14.6Ton |

17Ton |

20Ton |

22.9Ton |

25.8Ton |

28.7Ton |

31.5Ton |

|

Standard heating conditions |

||||||||||

|

Standard cooling conditions |

33 ℃ / 45 ℃ (cooling water) |

|||||||||

|

Power supply |

(220V\380V\440V)/3H/50Hz(60Hz) |

|||||||||

|

Drying temperature |

50 ~ 60 ℃ (return air) / 65 ~ 80 ℃ (supply air) |

|||||||||

|

Heat source |

Flue gas waste heat, steam condensate, generator waste heat, anaerobic digestion (gas-fired hot water) sludge cracking gasification combustion hot water production, etc. |

|||||||||

|

Control System |

Touch screen + PLC programmable controller |

|||||||||

|

Application scope of wet mud |

Moisture content (50% -81%) (other moisture content customized) |

|||||||||

|

Dry material moisture content |

Frequency conversion adjustment, moisture content (10% -50%) |

|||||||||

|

Forming method |

Cut |

|||||||||

Note 1: Product updates will cause changes in parameters, please contact technology for details. 2: For details of customized models, please communicate with technology.

Features

Waste heat utilization, heat recovery and utilization, energy saving 30%

Moisture content below 10%, reduction over 80%

Ultra-low operating cost per ton of mud at 50 kWh

50 degrees low temperature operation, safer

0 emissions, no odorous emissions, condensate can be discharged straight, more hygienic without dust